Top minerals for ceramic manufacturing

Ceramics are integral to a wide range of industries, from construction and engineering to refractory settings. At the heart of ceramic manufacturing lies the use of high-quality minerals, each carefully selected to deliver to desired physical, chemical and thermal properties. At LKAB Minerals, we supply a wide range of mineral solutions that enhance the performance and durability of ceramic products. Read this blog to find out more about some of our top minerals we offer that are used in ceramic manufacturing.

Chrome Alumina

Chrome Alumina from LKAB Minerals is a high-performance material made by fusing calcined alumina with chromium oxide. Known for its exceptional hardness and thermal resistance, it’s added to ceramics to increase heat resistance and improve structural integrity. It is also used in high-temperature kilns to produce advanced ceramics and bricks. In addition, it enhances thermal shock resistance, improves resistance to corrosive slags and chemical attack, and contributes to better wear performance for ceramics in abrasive environments. Its high-temperature stability and improved sintering behaviour make it ideal for producing dense, durable ceramic products.

Andricite

Andricite, LKAB Minerals’ synthetic anhydrite, plays a valuable role in ceramic and glass manufacturing. In ceramics, it improves thermal stability and structural integrity, making it ideal for applications that demand durability and heat resistance. In glass production, Andricite helps reduce defects and enhances overall product quality, offering a reliable mineral solution for high-performance manufacturing processes. Additionally, it acts as a consistent calcium source, contributing to fluxing behaviours during firing and helping to control thermal expansion. Its low loss on ignition and excellent particle size distribution support efficient processing and improved surface finish in ceramic bodies. Andricite also enhances glaze adhesion and can assist in reducing kiln atmosphere variability during firing.

Refractory grade Magnesite

LKAB Minerals’ Refractory grade Magnesite is a high-purity magnesium carbonate renowned for its exceptional heat resistance and chemical stability. In the glass and ceramics industry, it is utilised in applications such as glass tank regenerators and ceramic kilns. Its robust properties prevent contamination and ensure uniform heat distribution, thereby enhancing the quality and efficiency of production processes.

Its high refractoriness and low impurity levels make it ideal for high-temperature insulation and lining systems. Refractory grade Magnesite also contributes to slag resistance and thermal shock durability, extending the service life of furnaces and kilns. Its consistent mineralogy supports predictable performance and stability in demanding thermal cycles, making it a trusted choice in both traditional and advanced ceramic manufacturing applications.

Zircon

Zircon is integral to ceramic tile manufacturing, significantly enhancing both durability and visual appeal. Its incorporation into tile compositions strengthens the tiles, making them more resistant to wear and temperature fluctuations. Additionally, Zircon contributes to a superior finish, improving the tiles’ overall appearance and longevity.

Zircon enhances whiteness and opacity in glazes and bodies, ensuring that clean, high-end aesthetic. Its low thermal expansion helps reduce cracking during firing, and its high refractoriness makes it suitable for use in kiln furniture and advanced technical ceramics.

Mulcoa

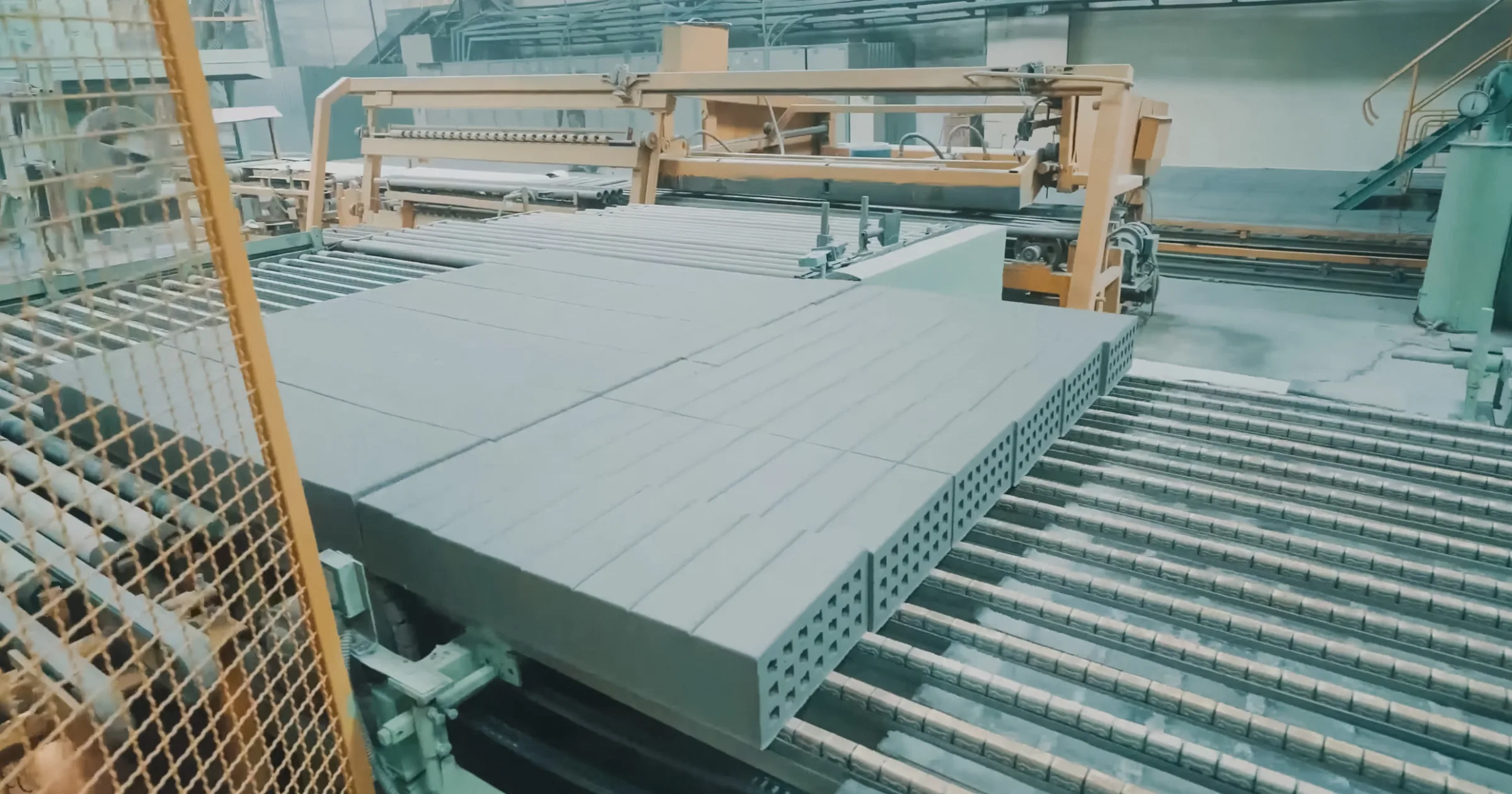

Mulcoa is a high mullite chamotte renowned for its exceptional thermal stability and strength. In the production of ceramic tiles and bricks, Mulcoa serves as a vital raw material, enhancing durability during high-temperature firing processes. Its consistent chemistry also makes it ideal for industrial ceramics, such as kiln linings and insulation, improving resistance to wear, thermal shock, and chemical corrosion. Additionally, Mulcoa is incorporated into clay-based products like ceramic pipes, sanitary ware, and electrical insulators, boosting their thermal and mechanical properties.

Its high mullite content ensures excellent refractoriness and dimensional stability, even under prolonged exposure to extreme temperatures. Mulcoa also promotes better drying and firing behaviour in ceramic formulations, reducing the risk of warping or cracking. Its controlled particle size distribution enhances workability, supporting efficient shaping and forming in both traditional and technical ceramic manufacturing.

At LKAB Minerals, we understand that ceramic manufacturing is both an art and a science. That is why we are dedicated to delivering minerals that meet the highest standards of purity, consistency, and performance. If you’re interested in learning more about how our mineral solutions can improve your ceramic production, get in touch with us today. To explore our full range of products, visit our product page, and follow us on LinkedIn to stay updated with our latest news and developments.